Applications

The HelioTrough® parabolic trough collector has been designed with focus for high power heat delivery application, mainly seen in solar thermal power plants.

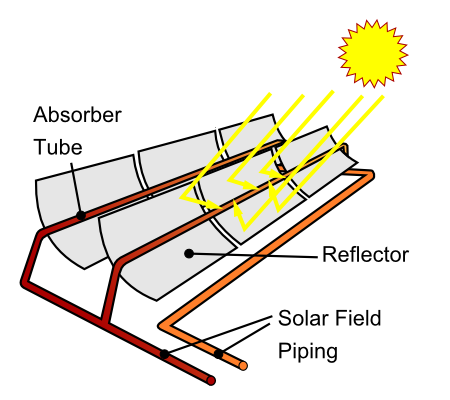

These plants consist of a solar field and a power block. In the solar field concentrating mirrors follow the sun's path and reflect the sunlight onto an absorber pipe located in the focus line of the mirrors. The heat transfer fluid (HTF) flowing through the heated absorber pipe takes over and delivers the thermal energy to the power block.

Trough Principle

In the power block the heat is transferred to a steam cycle. A steam turbine drives a generator that produces electricity like in a fossil fired power plant.

The solar field can be operated with thermal oil, molten salt or water / steam as heat transfer medium.

A thermal storage can be added to the plant design, enabling the delivery of thermal energy even after sunset or when clouds are passing by, stabilizing the power production.

Furthermore conventional power plants can be supplemented by a solar field to save fuel.

Another application is the industrial, solar process heat. The large amount of heat and steam in particular may be provided by parabolic trough collectors.

The demo plant in the United States demonstrates a reference value for the dimensions and performance: With 5052 m2, it provides about 3.5 MWt. The economic efficiency is reduced in smaller systems due to the mounting costs. The assembly of the collector elements is done by using high-precision assembly equipment (jigs) directly on site, as it is not practical to transport collector elements of 19 m x 6,7 m over long distances.