EuroPaTMoS

European Parabolic Trough with Molten Salt

Overall objective: cost reduction of molten salt parabolic trough technology to a bankable level

Project duration: 03.2021 – 11.2023

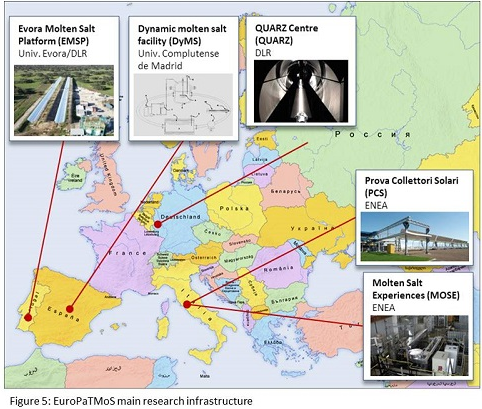

EuroPaTMoS pulls together the European expertise and testing infrastructure for parabolic trough (PTC) with molten salt (MS), to accelerate transfer of technology from R&D to commercial deployment. Two leading European CSP companies (TSK Flagsol and Rioglass Solar) join forces with three SMEs providing risk assessment and quality assurance services (CSP Services GmbH), quality assurance equipment and measurement services (CSP Services España), electrical scope and operating teams for CSP (Ductolux) to develop a selling proposition with reduced risk and competitive cost.

This industrial endeavour is supported by a strong R&D complement consisting of two large R&D institutions (the German DLR and Italian ENEA) and three Universities (Uni Complutense Madrid, Uni Extremadura, both Spain, and Uni Evora, Portugal) with complementary specializations and abilities. Together they gather two of the most important European infrastructures for PTC-MS research and specialized lab and technical scale facilities for component testing and investigation of corrosion and salts degradation issues.

This unique constellation of independently funded partners at national or regional level enables the consortium to tackle all topics by parallel investigations on the different test facilities, integrating the results and experiences of previous and ongoing projects in this field. In particular, the following issues will be addressed:- Evaluate critical plant components regarding reliability (review of consortium joint knowledge, laboratory testing, and operation in realistic environment).

- Develop a process control concept based on a virtual solar field, to be validated on a full size collector loop enabling hardware-in-the-loop simulation of a full solar field.

- Develop and demonstrate O&M procedures for exceptional molten salt operations (e.g. filling, draining, repair of leakages, re-vitalizing frozen parts).

- Carry out and document systematic risk assessment including mitigation measures. Develop high performance receiver tube and validate in relevant environment.

- Provide methods and equipment for advanced QA and monitoring during construction and operation of PTC-MS solar fields

TSK Flagsols Teil des Vorhabens EuroPatmos wurde mit Mitteln des Bundesministeriums für Wirtschaft und Energie unter dem Förderkennzeichen 03EE5059B gefordert. Die Verantwortung für den Inhalt dieser Veröffentlichung liegt beim Autor.